Diffusion Bonding

Pushing shape boundaries.

“Each year, the demand for highly precise and intricate machined shapes continues to grow. These shapes are essential for enhancing the performance of the equipment they are integrated into.

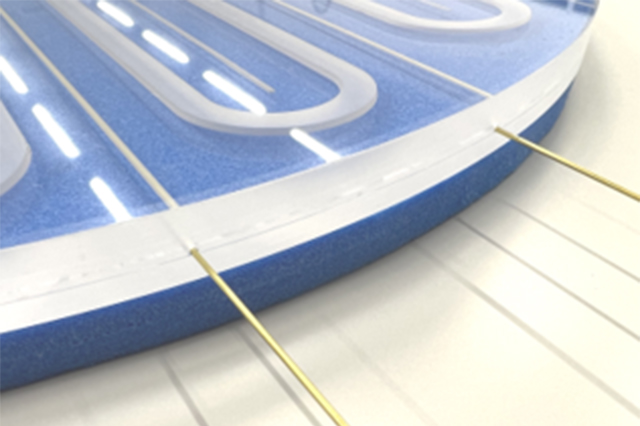

In addition to our traditional precision machining capabilities, we have been actively developing diffusion bonding technology to meet the increasing demand for enhanced performance. Unlike adhesives or brazing, diffusion bonding offers direct bonding, eliminating concerns about differences in heat resistance or linear expansion coefficients. This technology also simplifies the creation of internal coolant and gas flow paths, enabling the design of innovative shapes and solutions.

By combining our extensive experience in precision machining with our newly introduced joining technology, we are now capable of realizing shapes that were previously challenging to achieve, thus contributing significantly to resolving our customers’ technical challenges.”

| Materials |

“Joint Achievements: Molybdenum, Nickel, Quartz Glass, SiSiC, Alumina, Columnar Silicon””

(*These are joints of the same materials.) (*We are also experimenting with other materials.)” |

|---|---|

| Helium leak rate |

“Below 1.0×10^-9 [Pa·m^3/sec], achievement has been reached with test pieces for any of the above-mentioned materials. (Helium leak detector installed, capable of measuring down to 1.0×10^-11 [Pa·m^3/sec])” |

Product Examples

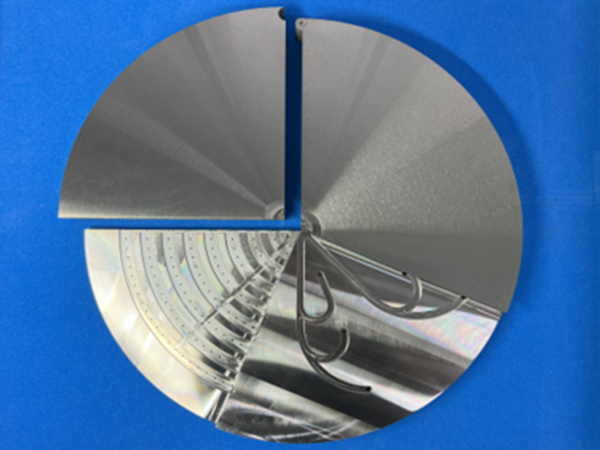

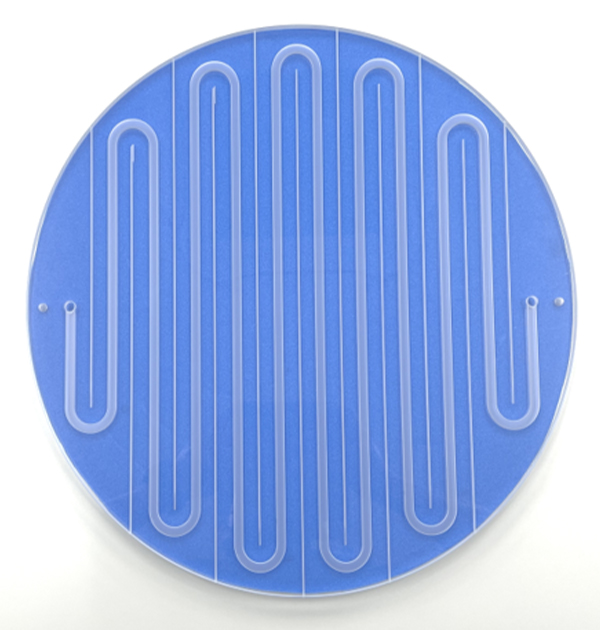

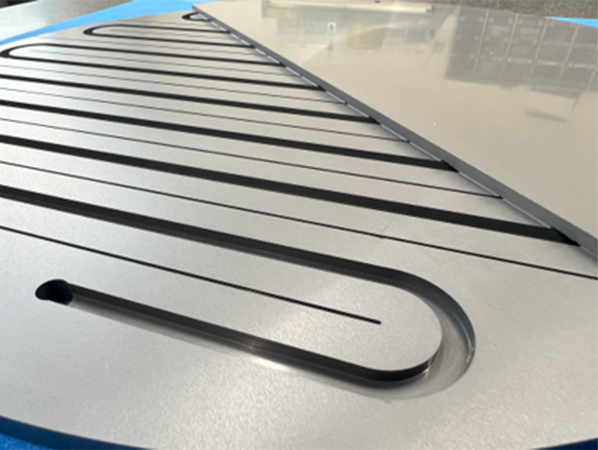

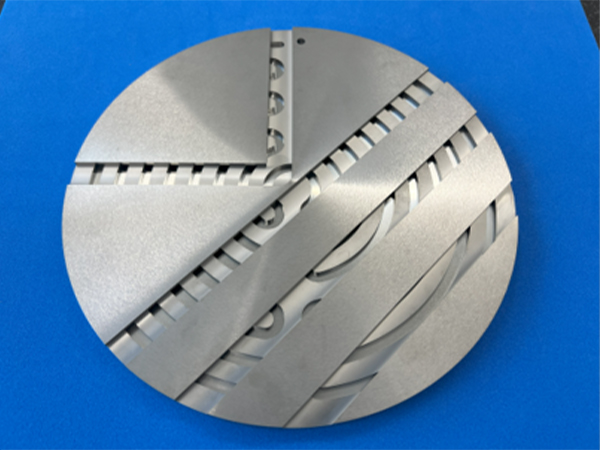

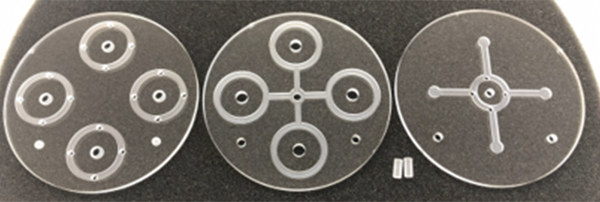

Nickel

ø310, 3 internal flow channels, diffusion bonded.

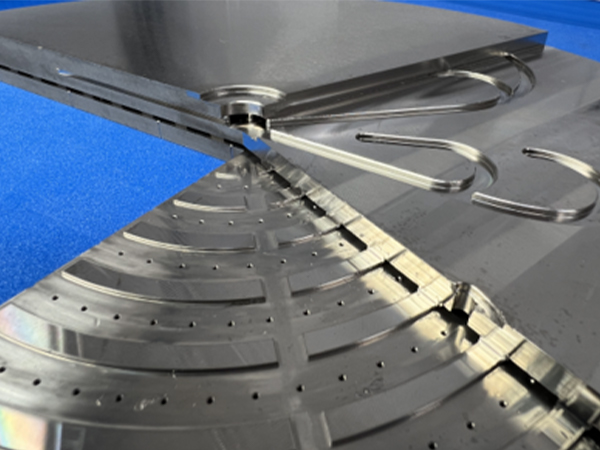

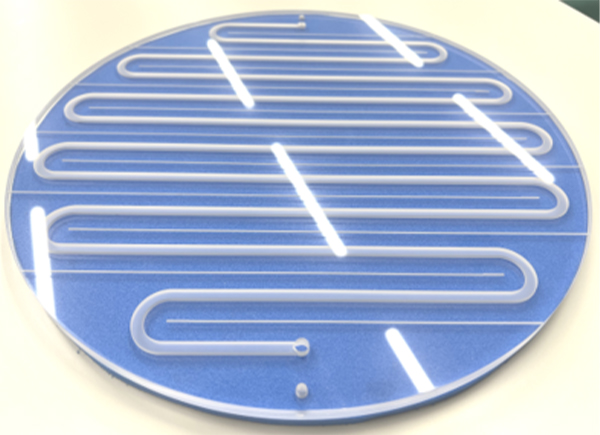

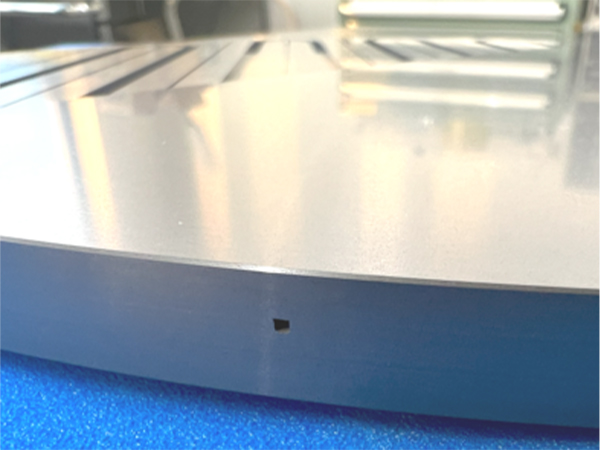

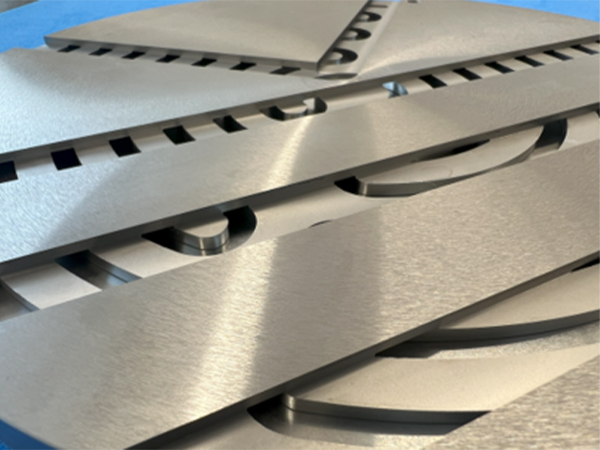

SiSiC

φ300mm, 3 pieces welded, cooling grooves, side holes

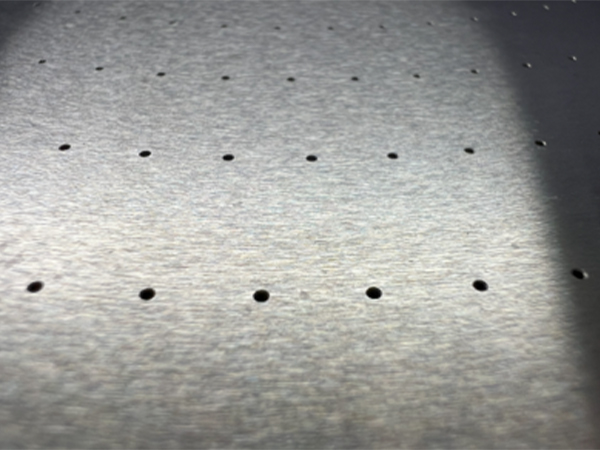

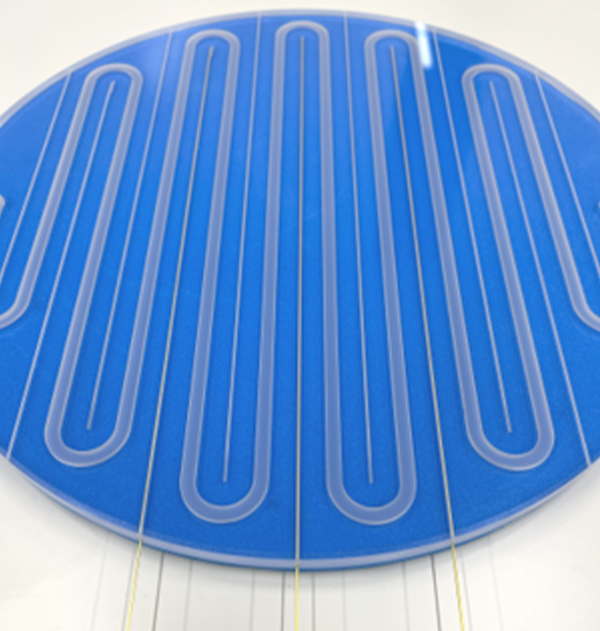

Quartz glass

ø390mm, 2 pieces welded, inner flow channel, side holes

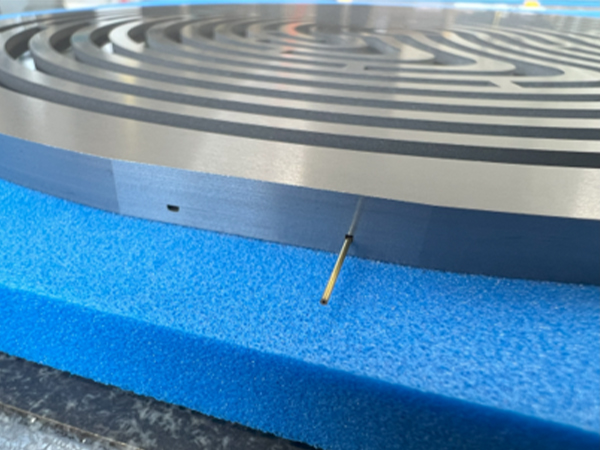

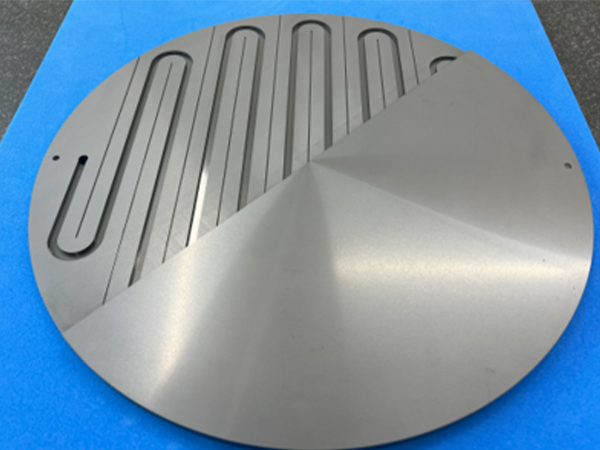

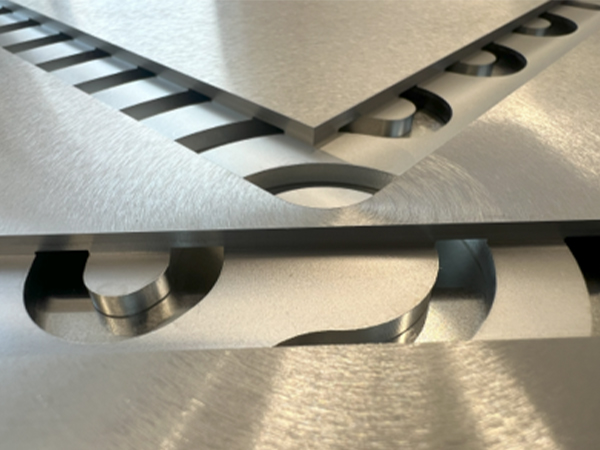

SiSiC

φ390mm, 2 pieces welded, inner channel, side holes.

*Result of inner channel helium leakage measurement: 6.0×10-12Pa-m3/sec or less (target value achieved).

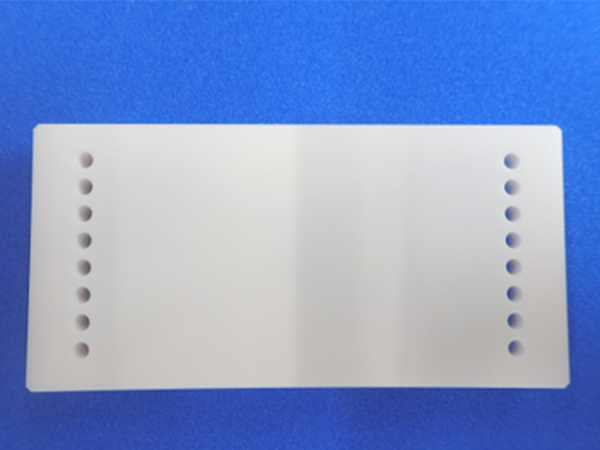

Alumina

50x100mm, 2 pieces welded, internal flow channels

Molybdenum

φ270mm, 2 pieces welded, internal flow channels. Result of helium leakage measurement in internal channels: 5.0×10-11Pa-m3/sec or less (target value achieved).

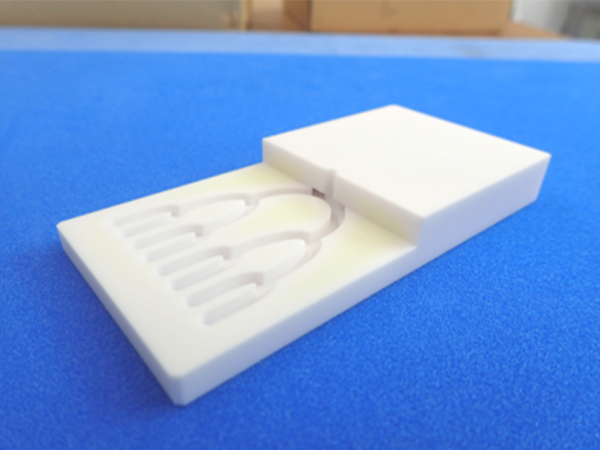

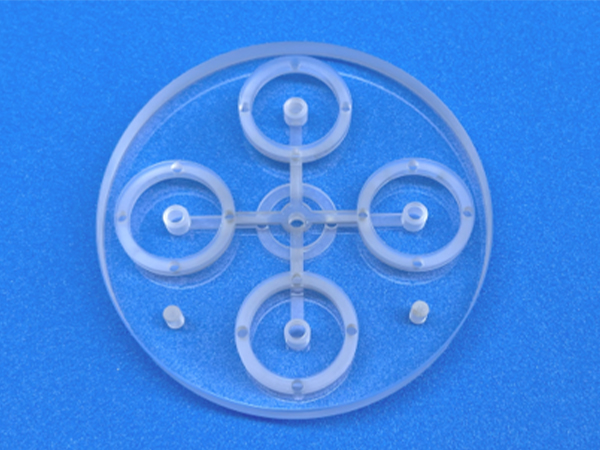

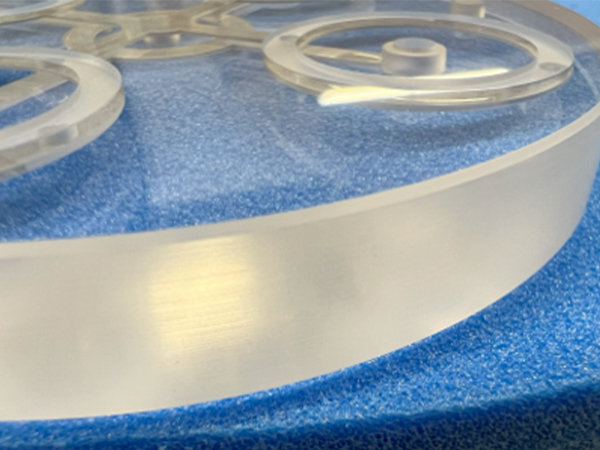

Quartz glass

φ96mm, 3 pieces welded, 2 internal channels